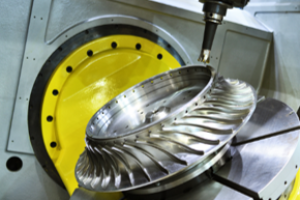

BRC’s mould design process integrates advanced engineering software such as ProCAST simulation and SolidWorks CAD/CAM. These tools allow us to model, simulate, and refine moulds before production begins, reducing errors and ensuring dimensional accuracy.

Prototyping capabilities further support customers in validating designs and optimising performance before full-scale manufacturing.